The technologies we are using to produce our lamp components are also fit for other applications. Learn more on this page.

The technologies we are using to produce our lamp components are also fit for other applications. Learn more on this page.

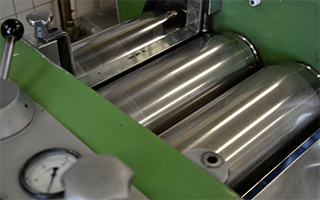

Mixing is done with a variety of machines, each with it's own possibilities for the best result.

The process of particle enlargement by agglomeration technique or granulation is available on three platforms. This process transforms fine powders into free-flowing, dust-free granules that are easy to compress.

Our milling machines can handle any particle size you need.

The term sieving commonly refers to the separation of a ground mass of material into various particle-size classifications. Separation by a sieve is normally accomplished by the movement of the material on the sieve screen, which causes the particles smaller than the mesh opening to pass through by the force of gravity, and the particles bigger than the mesh opening to stay on the screen.

Different products need different mixing platforms. For powders, viscous materials, emulsions, suspensions and lyosols we use different techniques.

Separating liquid from solid content can be done by different techniques.

Pressing is a forming process that applies pressure on a powder to create a compact part, achieving high precision parts with maximum uniformity of density and microstructure.

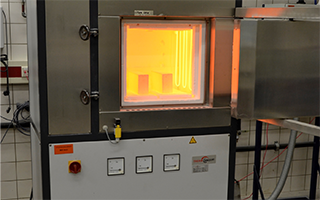

With the sintering of our ceramic rings we eliminate the last bit of moisture and make the rings fit for direct use. Packed in an air tight glass jar they are shipped out over the whole world.

For the printing of substances on hard surfaces such as glass, we use a screen printer. This printer is positioned in a dust free room to prevent any impurities on the print.

We can deliver legendary quality thanks to verticaly integration including our best glass in industry, our own suspension produced in own suspension room, a reliable coating process, all done under the eyes of our well-trained crew and engineers.

Thanks to a wide range of equipment, we not only offer huge capacities, but also a great deal of flexibility.

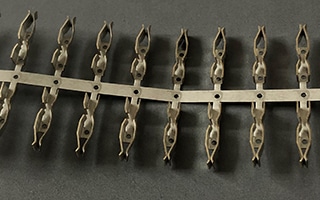

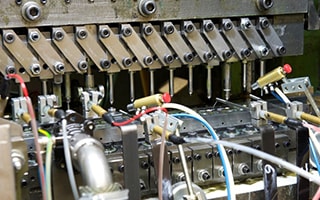

Progressive and transfer stamping tools are designed in-house. High complexity tools very often include own solutions to guarantee maximum precision and high quality of details. Special materials with specialized coating used for working parts are also available.

Many of the processes are realized on automated high-speed lines using servo robots, pick and place units and vision system control. Often includes special testing, leak & electrical testing and individual packaging in trays.

In the electroplating shop, equipped with an automatic line, very high-quality nickel plating of bulk parts is ensured.

Ultrasounds washing - Using different methods by solvent or aqueous solutions - the surfaces of the parts are cleaned, free of oils and solid soil particles.

Deburring - Applying mechanical and chemical processes, the contours are smoothed at the edges - even in hard to reach places

Tumbling - This mechanical process smoothes the surfaces. The abrasive bodies are mixed together with the work pieces and an aqueous solution and then are set into vibration.

Modern injection machines integrated with robots. Millions of parts meet the highest quality requirements of the automotive market. Experience in the processing of difficult materials such as PPS and thermoset resins. Metal parts are inserted into the tool and injection molded with plastic. The end products are called hybrid parts. Automated machinery for thermoset resins processing.

Specialised in application of high quality progressive and transfer tools over 45 high speed stamping and transfer presses supported by years of experience in different material types: carbon steel, stainless steel, aluminium alloys, copper alloys, copper coated. Punching technique are combined with bending and stamping process. This allows for complex finished parts - according to individual wishes of customers. Different material thickness ranging from 0,18 mm up to 1,5 mm and different details shapes are worked with.

Besides typical sheet metal forming operations, several highly specialized technologies are used to perform all sorts of additional functional features such as threads, side wall extrusions and side wall piercing.

Highly precise details within very tight tolerance range difficult materials like: stainless steel, spring steel, special coated copper alloys the stamping range includes many of stamped and bent metal parts.

Products

Our lamp components find their origin in the manufacturing of lamps, however these same components or derived components can also be used for other purposes.

Applications

Our components are applicable in a wide range of lamps, from GLS (incandescent) and halogen lamps to TL and CFL (fluorescent) lamps as well as HID (high intensity discharge) lamps.