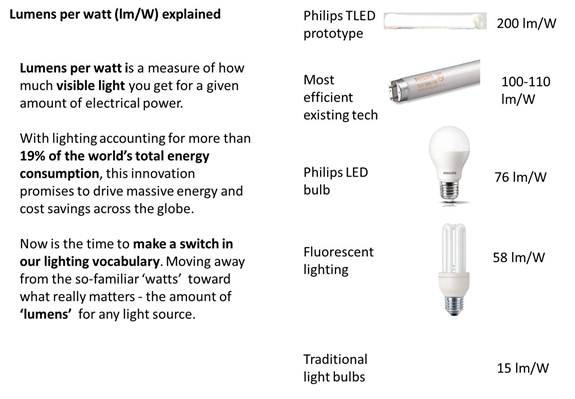

Philips is the world’s first to present a lamp prototype that produces a record 200 lumen per watt (lm/W) of high quality warm white light. This LED technology breakthrough brings energy-efficient LED light suitable for general lighting applications to a whole new level. The 200lm/W LED is expected to hit the market in 2015 and will ultimately be used in a wide range of applications.

The challenge of achieving the 200lm/W goal

In the industry’s effort to break the 200lm/W barrier, the challenge is to achieve higher efficiency levels at lamp/system level (demonstrated in an end product prototype under real, normal conditions and ready to be incorporated into actual products). Until now, similar efficiency levels have been achieved in a cool and controlled lab setting or on component level, however, when placing the solution in a lamp it could lose up to 50% of its efficiency. Furthermore, to be suitable for real-world applications, the light produced by LEDs must fall within certain technical parameters. If it is too cool or too warm in color, or lacks a sufficient quantity of red, it will interfere with the way the human eye perceives color, and will give objects an unnatural tint. Yellow/green emitting LEDs obtained by phosphor conversion, for example, are extremely energy efficient (providing more than 380lm/W), but practically useless for general lighting purposes.

In technical terms, general lighting applications require a color temperature of 3000–4000 kelvins, a color rendering index of at least 80, and an R9 (level of saturated red) of no less than 20. It is within this context that the magnitude of Philips’ achievement must be understood. Philips’ TLED protype produces 200 lm/W without scarifying color rendering index and staying on the black body line.

How are white LEDs created?

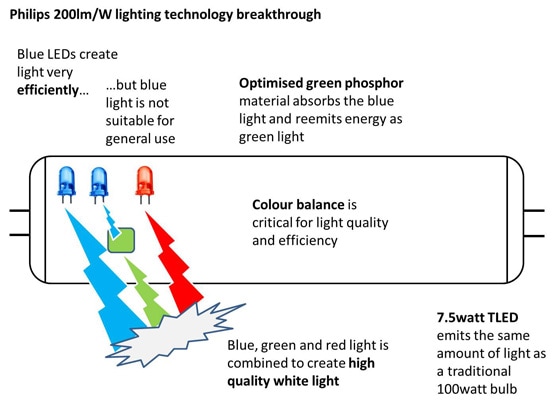

There are currently two ways to make white light with LEDs. One method mixes multiple wavelengths of different LEDs to make white light (i.e. RGB); allowing the lighting designer to tune the white light to a specific color temperature.

The second method uses a blue Indium-Gallium-Nitride (InGaN) LED with a phosphor coating to create white light. This is the method that results in the more commonly seen “white LED”.

But now Philips is using a new approach, which combines blue, green and red light to create high quality white light: